Planning a new bridge construction project is never an overnight success. Construction projects are stressful, time-consuming, and hectic. Construction teams need to meticulously follow numerous steps to ensure their project goes off without a hitch.

If your team is about to undertake a new project, you should familiarize yourself with the five phases of project timelines in bridge construction. When you understand the phases your team will undertake, you can prepare for each one in advance. Not only will this foresight prevent feelings of confusion and defeat, but it can also help you effectively prevent incidents like delays and cost overruns.

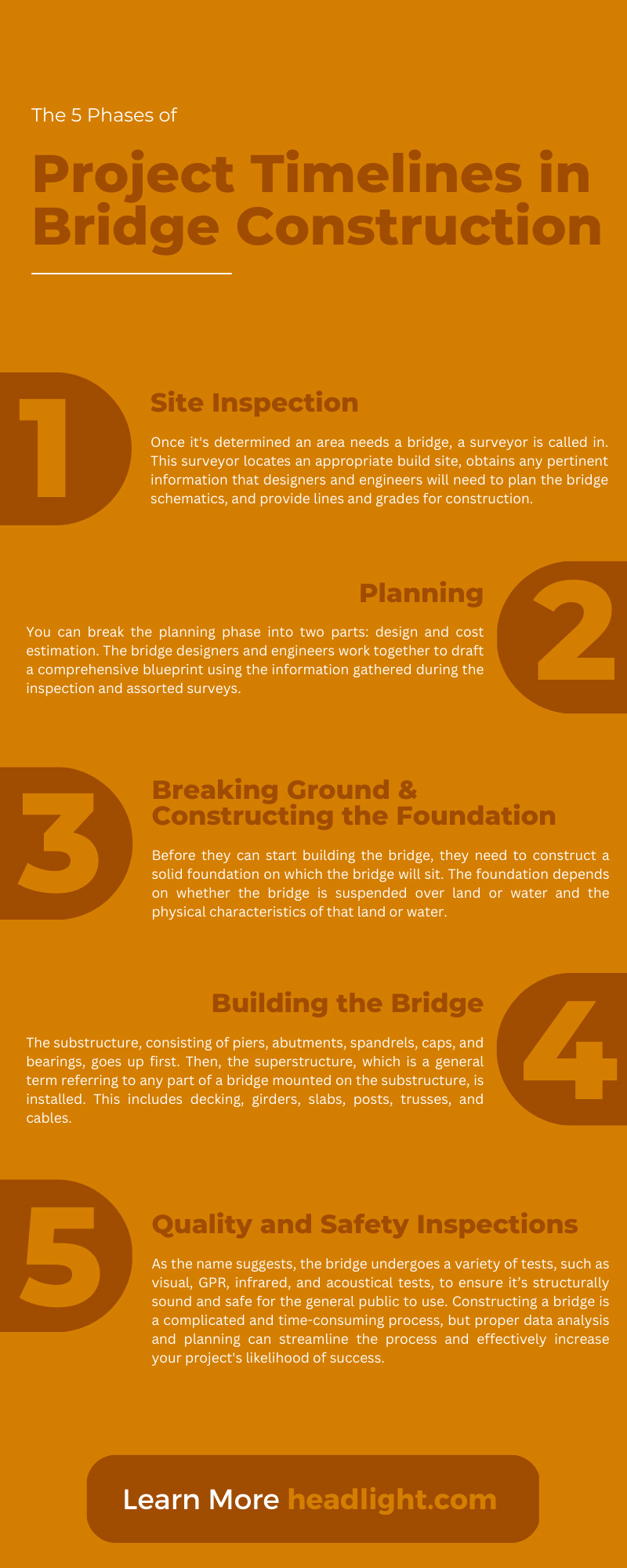

Site Inspection

The first phase of bridge construction is the inspection. Once it’s determined an area needs a bridge, a surveyor is called in. This surveyor locates an appropriate build site, obtains any pertinent information that designers and engineers will need to plan the bridge schematics, and provide lines and grades for construction.

After the surveyor completes their work, the construction site is sectioned off, graded, and cleared. Any buildings, foliage, and underground infrastructure (such as pipes or wires for water, electricity, gas, telecommunications, etc.) are removed. Then, the site engineer performs geotechnical soil testing on-site. The soil determines the most suitable type of foundation and bridge materials for the project. A soil sample is collected, sent to a lab for testing, and graded according to its tendency for movement. If the site is on a river, a hydrological survey performed by a licensed hydrographer is also necessary.

Planning

With the site chosen and cleared and a variety of geotechnical and topographic information in hand, construction crews can move on to the next phase: planning. You can break the planning phase into two parts: design and cost estimation. The bridge designers and engineers work together to draft a comprehensive blueprint using the information gathered during the inspection and assorted surveys.

To start, they create several conceptual designs, which are rough sketches meant to demonstrate what the finished bridge will look like. After selecting one of the conceptual designs, the architects and engineers draw a preliminary design, which gauges the feasibility and cost of the chosen concept. Once that’s approved, they finalize minor details with a comprehensive design and provide step-by-step instructions for building the bridge with a construction design.

The cost estimation part of planning can start once the preliminary design is available. The crew assesses the design; estimates how much the labor, materials, permits, and other fees will cost; and comes up with an approximate budget.

Breaking Ground and Constructing the Foundation

Workers can break ground once the planning phase is complete and all necessary construction permits and legal documents are acquired. Before they can start building the bridge, they need to construct a solid foundation on which the bridge will sit. The foundation depends on whether the bridge is suspended over land or water and the physical characteristics of that land or water.

There are two types of foundations used for land bridges: shallow and deep foundations. Shallow foundations are generally used on sites with dense, stable soil. They feature a wide base that sits on the topsoil. They transfer the load of the bridge onto this soil. Deep foundations, on the other hand, are necessary for sites with loose, loamy, and unstable soil that can’t bear the weight of a bridge on its own. They’re typically formed via piling, which involves driving narrow piles into the ground with a pile driver.

Building a foundation for a water bridge is tricky. However, builders can use a variety of techniques to create sturdy underwater bases. Battered piling, cofferdams, and slurry drilling are the three most utilized methods.

Battered Piling

Battered piles are commonly used to support bridges in areas with shallow water. Battered piles consist of multiple deep, angled beams arranged in a fork-like formation. They’re carried to the construction site via a barge and dropped into the water. From there, they’re driven into the soft river, lake, or ocean bed.

Cofferdams

In some cases, it’s necessary to construct a cofferdam, which is a large, watertight enclosure pumped out to create a dry zone for foundation construction. This method is costly, time-consuming, and dangerous; it’s typically only used for bridges that require massive support towers.

Slurry Drilling

The soil at the bottom of a body of water tends to be extremely soft. Drilling directly into this soil is risky, as the ground could cave in. As an alternative, workers drill a hole by displacing the soil rather than extracting it. They do this by introducing a muddy mixture of cement and water, called a slurry, into the hole as they drill it. This stabilizes the sides of the hole and prevents it from collapsing.

Building the Bridge

With a stable foundation in place, workers can begin constructing the bridge. The substructure, consisting of piers, abutments, spandrels, caps, and bearings, goes up first. Then, the superstructure, which is a general term referring to any part of a bridge mounted on the substructure, is installed. This includes decking, girders, slabs, posts, trusses, and cables. After completing quality assurance testing, workers install additional components, such as paving and electrical systems. They can also choose to paint or stain the bridge to seal it and give it an attractive cosmetic finish.

Quality and Safety Inspections

With the bridge built, the team moves onto the final phase of a bridge construction project timeline: quality assurance. As the name suggests, the bridge undergoes a variety of tests, such as visual, GPR, infrared, and acoustical tests, to ensure it’s structurally sound and safe for the general public to use.

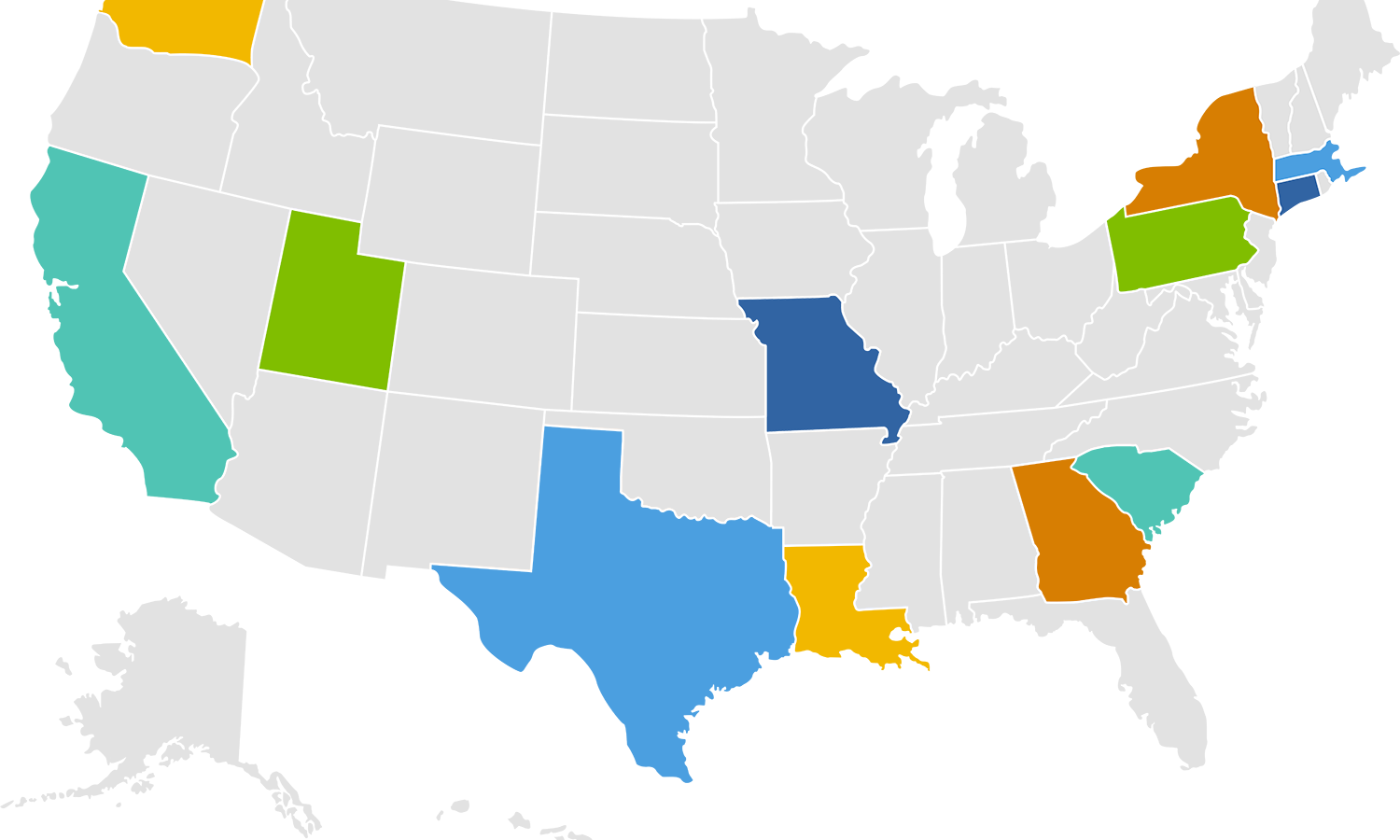

Constructing a bridge is a complicated and time-consuming process, but proper data analysis and planning can streamline the process and effectively increase your project’s likelihood of success. At HeadLight Technologies, we provide construction management and planning programs that help you complete your project from start to finish. Our construction field reporting software helps deliver quality infrastructure on time with digital data collection and visual-based inspection. If you have questions regarding our construction programs and software, our professional team will guide you in the right direction.