The stormwater and wastewater infrastructure industry is experiencing a major squeeze: the cost of materials, labor, and equipment have all risen due to inflation and other factors. As such, margins are being squeezed and it’s unclear if the ambitious goals set following the influx of federal funding will be met.

The impact of rising costs

According to a recent article in Construction Equipment, the Water & Wastes Digest annual State of the Industry survey saw respondents indicate “that they will have an increase in their budget for 2023 (66 percent) or no change (28 percent) with 7 percent expecting a decrease. This change aligns directly with the increase in operational costs that utilities are facing as 93 percent witnessed an increase year over year.” Water utilities are doing their best to compensate for this shift—but the result for some is bound to be reduced efficiency.

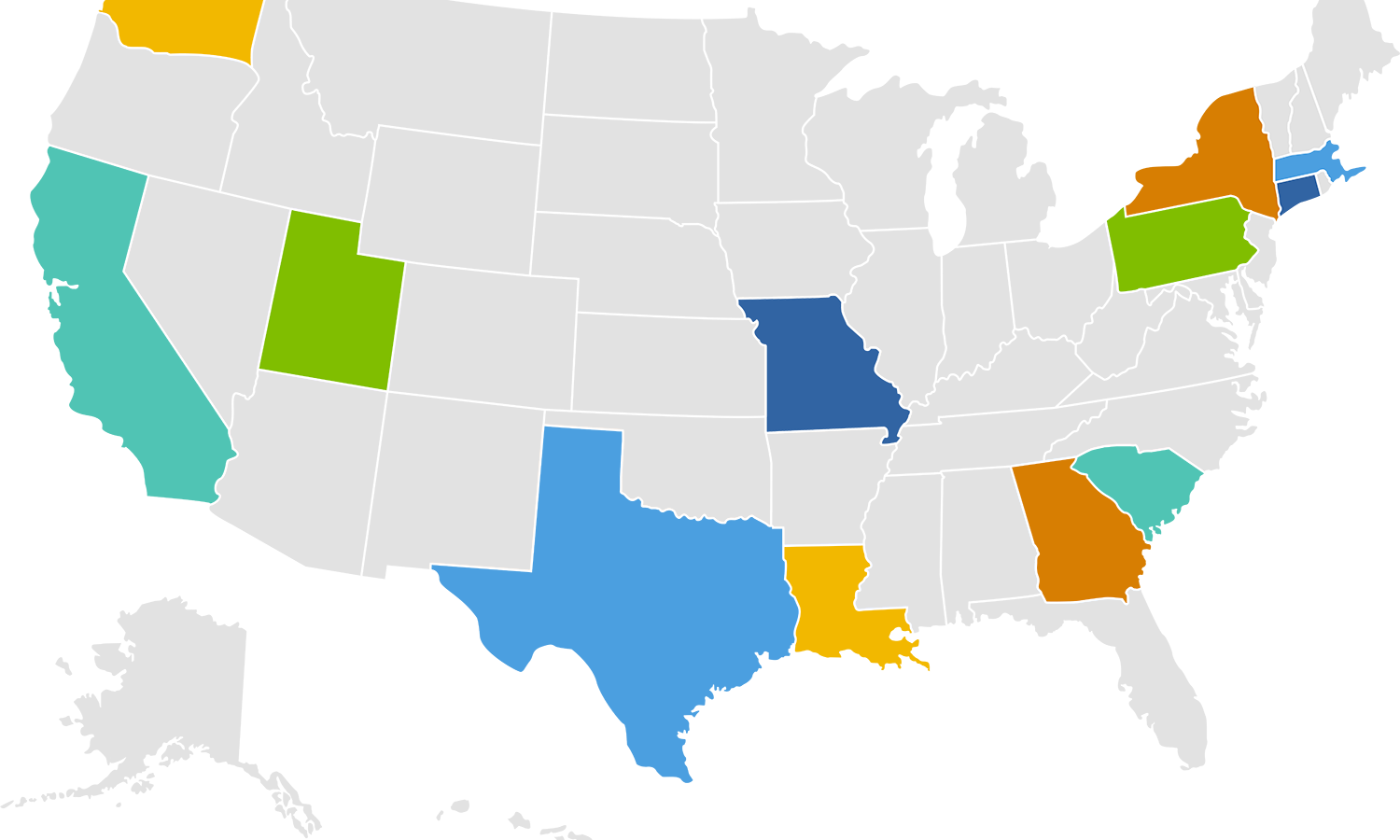

What’s more, Circle of Blue states that the cost of lead service line replacements for Michigan’s Department of Environment, Great Lakes, and Energy has increased by several thousand dollars per line. As a result, “some communities are having to reduce the scope of the work, a downgrade that will lengthen the amount of time that the toxic pipes remain in use.” We can expect these sorts of skyrocketing prices for pipe replacement exist around the country. Which means municipalities are feeling significant budgetary constraints, from coast to coast.

In response to rising prices, water utilities are also:

- lengthening project timelines

- breaking projects into distinct segments

- absorbing the costs altogether

Federal funding: hit or miss?

In 2021, the stormwater and wastewater infrastructure industry saw a historic investment of federal funding: The American Rescue Act and the Infrastructure Investment and Jobs Act (IIJA) each allocated billions of dollars towards crucial water industry needs such as repairing water and sewer infrastructure. Subsequently, water utilities set ambitious goals and planned to carry them out in the months and years to come.

But the industry is being squeezed: leaders are aiming to achieve their critical and ambitious goals—yet must adjust their plans to consider rising prices. This could potentially lead to slowed progress and hinder the industry’s initial vision for efficient infrastructure repairs and improvements.

But there is a way for the water infrastructure industry to accomplish more, even while being squeezed. Private engineering firms, private utilities, and public municipalities can maintain and improve systems with efficiency while counterbalancing the increasing cost of materials, labor, and equipment by embracing the efficiencies of technology.

How technology offsets rising costs

Despite the challenges posed by increased costs, construction firms that deliver water projects and water utilities can still navigate the challenges of inflation by equipping their teams with solutions and tools that save time and money.

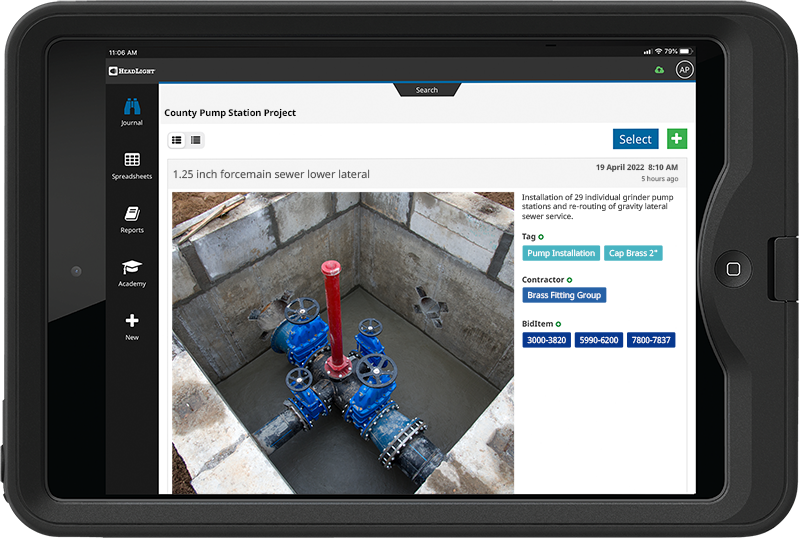

Tools that eliminate duplicative data entry, help catch costly errors thereby reducing rework, and enable collaboration helps teams deliver on time and on budget. Our water solution not only offsets the short-term challenges posed by rising costs—but provides significantly improved efficiency, reduced risk, and improved collaboration for years to come.

The value of digital construction management solutions

Inflation is beyond the water infrastructure industry’s control—what can be controlled is: reducing errors and maximizing efficiency. Equipping teams with a digital construction management solution means:

- Getting the work done with the time and people available

- Delivering infrastructure on schedule

- Making fewer mistakes

- Reducing rework

- Reducing claims

- Improving collaboration through easily accessible, accurate data in the cloud

Our solutions have been used on water projects with a total value of more than one billion dollars. More than 22 private firms and many public entities are using HeadLight to deliver water projects that are well-documented and collaborative.

Real-life examples include Seattle Public Utilities and King County Wastewater Treatment’s Division collaboration with Jacobs Engineering Group on an underground storage tunnel project as well as Fresno County’s Creek Fire Erosion and Sediment Control Project.

HeadLight’s inspection and verification technology provided instant value to both projects; having access to real-time, accurate data allowed for significantly enhanced collaboration, more consistent documentation, clarity in data relationships, and reduced risk.

Take a closer look at our solutions and learn how our flexible tools perfectly suit the needs of the water infrastructure industry by requesting a demo today.