Challenge

Jacobs, a large construction and engineering firm, is delivering a large, 5 year, $500+ million stormwater and wastewater overflow storage tunnel in Seattle, Washington. The work is being done almost entirely underground and involves large, complex machinery and exacting timelines.

Solution

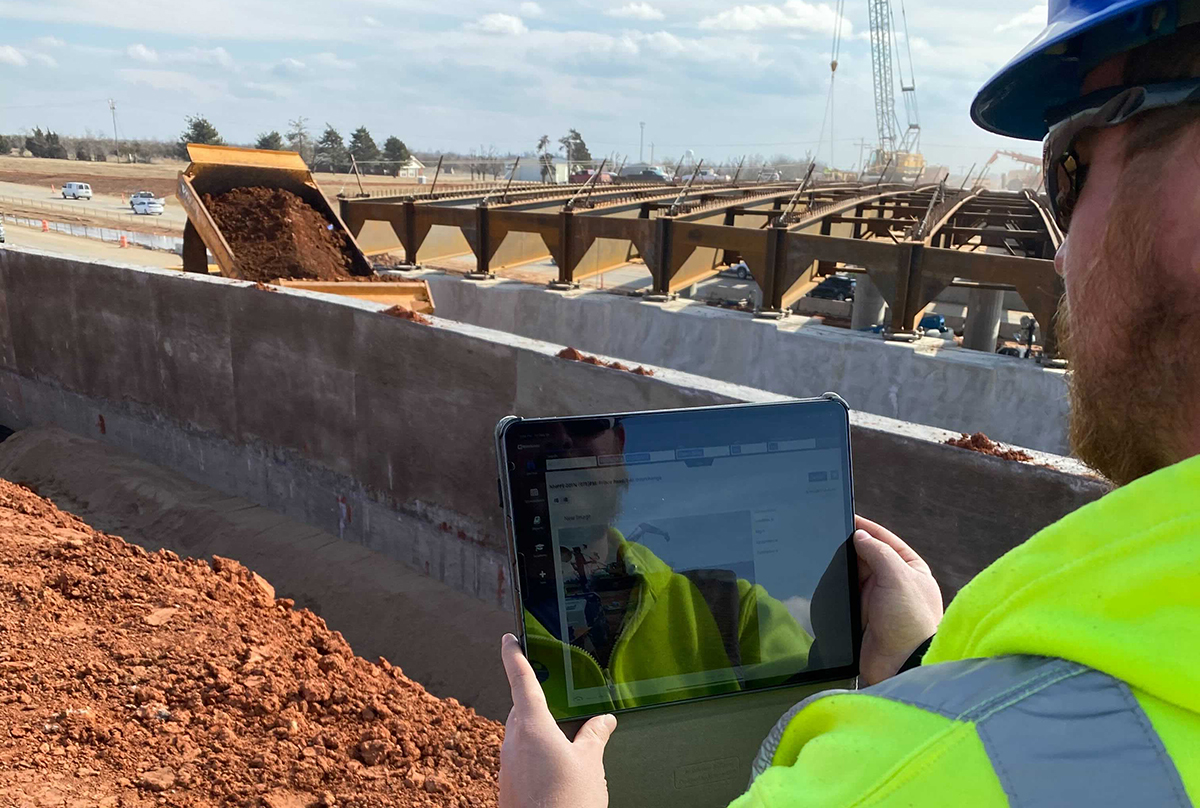

Jacobs is using HeadLight’s Fieldbook app to collaborate between the office and the field via real time data access, to digitize and streamline workflows, and to improve their partnership with project Owners: Seattle Public Utilities and the King County Wastewater Treatment Division.

Results

This project is still in full swing, but thusfar, Jacobs reports enhanced collaboration and communication between team members and across teams and increased protection against claims thanks to unassailable documentation.

The Full Story

Project Overview

As part of the continued investment into the health of the Pacific Northwest region, Seattle Public Utilities and King County Wastewater Treatment Division are building an underground storage tunnel to prevent an average of 75 million gallons of polluted stormwater and sewage from entering nearby waterways like Lake Washington Ship Canal, Salmon Bay and Lake Union from the sewer system. This tunnel will capture any overflow from the combined sewer pipes and temporarily store more than 29 million gallons of untreated stormwater and sewage. This will improve regional water quality and reduce impacts on fish, wildlife, and the local environment.

SEATTLE, WA

LOCATION

5 YEARS

DURATION

$570,000,000

PROJECT VALUE

DESIGN-BID-BUILD

PROJECT DELIVERY METHOD

ROI

TIME & MONEY SAVED

Significant reduction in inspector overtime

PROJECT VISIBILITY

More accurate project information shared across teams

REDUCED CLAIMS

Improved protection against claims

Goals

In many cities like Seattle, a combined sewer system is quite common. A combined sewer system collects rainwater, domestic sewage, and sometimes industrial waste, carrying it to a treatment plant. As cities grow, in concert with larger storms and climate change, the risk of overflows increases. Heavy rains cause pipes to become full, resulting in an overflow of untreated water. This can have negative health impacts on local citizens, cause beach closures, and contaminate other bodies of water. It can also have adverse effects on the environment, causing toxic algae blooms and harming fish and wildlife.

To prevent polluted water overflows, Jacobs Engineering Group has been hired as the Construction Management consultant for this complex public infrastructure project. A main priority of this project is to build an underground storage tunnel to store overflows until they can be transported to the treatment facility. This 2.7 mile long tunnel will run from the Ballard to Wallingford neighborhood, measure just under 19 feet in diameter, and be buried 40-80 feet below ground. The tunnel is connected to the original sewer lines via a series of diversion drop structures. A tunnel boring machine, called the Mud Honey, is being used to excavate the space necessary to construct the tunnel and associated diversion shafts. The subterranean location of this project requires additional effort and thought into how teams will effectively communicate project updates while maintaining safety. Additionally, tunneling projects have unique reporting requirements. All of these considerations were brought to bear as Jacobs Engineering Group evaluated their construction inspection technology.

Investing in the most effective inspection and verification technology:

- Enables real-time trouble-shooting from the jobsite thereby allowing work to move quickly and minimizing inspector overtime

- Provides a higher level of oversight by allowing the construction manager, engineering teams, and the project owner immediate access to project data

- Creates a customized daily report format, which streamlines daily administrative tasks

- Ensures data integrity, consistency, and transparency

- Improves accountability and transparency across teams

Challenges

The complexity, scale and timeline of this Design Bid Build project demands technology solutions that support accurate, easily findable reports and observations. Additionally, the team needs to be able to make inspection progress and maintain safety standards, even when offline and underground. Exact GPS locations, combined with images, annotations and other meta data is required to be to address and remedy potential issues as quickly and as efficiently as possible.

The Solution

FIELDBOOK

HEADLIGHT PRODUCTS

11

HEADLIGHT USERS

Having enjoyed success on the Seattle Waterfront project and Tacoma Link project, the team at Jacobs chose to continue using HeadLight’s cloud-based solution. The ability to connect the field to the office in real-time allows teams to collaborate remotely. The team is able to make inspection progress and maintain safety standards, even when offline and underground. For example, Jacobs inspectors are able to identify potential issues and provide photo documentation that includes comments along with the exact GPS location to all necessary stakeholders within the same day. This empowers the team to swiftly resolve concerns based on reliable data from the field, preventing accidents and costly delays.

The inherent flexibility of HeadLight’s technology allows the team to track project progress easily as well. Observations taken in the field include metadata, like GPS locations and timestamps, creating a visual log indicating which segment of the tunnel is being worked on. Each inspector’s daily report automatically includes this data, which helps to minimize inspector overtime by reducing the administrative burden.

Headlight’s Fieldbook unifies the Jacobs team with a single source of truth. Construction project inspectors are able to collect rich data, including photos and videos, and are able to track equipment and personnel in the field. Teams are unified by shared data and are able to share information with project stakeholders in near real-time.

Outcomes

By incorporating HeadLight’s technology into their strategy, Jacobs engineers are able to identify and resolve jobsite issues. The team is also able to provide consistent, quality reporting to the client as well as reduce inspector overtime. Reports include embedded photos, providing indisputable evidence of the project’s quality.

Storing data on the cloud enables all stakeholders to easily gain visibility into project information regardless of physical location. Data integrity, consistency, and transparency across the organization had multiple benefits—both during pre-construction and during construction work on the SPU Ship Supply Water Quality project. They include:

- Enhanced collaboration and communication between team members and across teams

- Improved accuracy of project information through access to digital reporting and data validation tools

- Consistency across documentation

- Risk reduction and protection against claims thanks to unassailable documentation

While Fieldbook brings instant value to this project by providing real-time data during construction, Seattle Public Utilities and King County will also benefit for years to come by having access to archived, well-organized data.